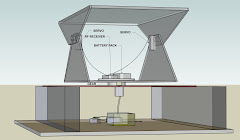

- Construction continues and design flaws are addressed (original Cable pipe could not be stuck to the pan part and so have had to rivet a milled out piece of aluminium) Rivots have been used for connecting a frame.

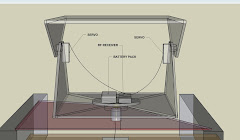

- Found that servo's pivot range is more than adequate and so no further alterations are needed.

- Will not dip coat but will spray the head at the end.

- Had difficulties lining up the gear and the motor for the pan mechanism.

- Found a much more reliable method of connecting the servos onto the pan and tilt parts.

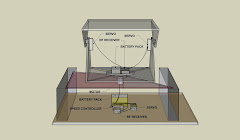

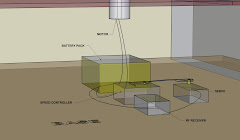

- Box was built to house electronics and form the base of the head.

- Swivel plate seems to be rotating well.

- Had difficulties fixing the gear to the pipe but after milling the gear to the correct diameter it slipped on easy. Etched teeth into the pipe to hold the gear.

- All holes cut.

- Will next have to wire in extension cables for servos and mount the rest of the electronics.

January until April 2009

Subscribe to:

Comments (Atom)

.jpg)

.jpg)