LAST UPDATED 12TH JULY 2010

Exhibition Videos

Here is a video of the Z1 test and initial thoughts are that it is slightly more sluggish than with the consumer JVC camera. This is in part due to the resolutions from each camera being different. The JVC is giving out 640X480 (a standard 4X3 resolution) whereas the Sony Z1 is giving a resolution of 720X576 (a standard 16X9 resolution). This means the X position doesnt quite catch up as fast as the Y position. This also results in more processing time being needed for the larger resolution to firstly process the incoming video signal and then add the recognition software. A way to help with this might be to ensure the digipot for the X coordinates has full resistance or 0V at a point which isnt at the edge of the screen and the same for no resistance or 24V.

Z1 Test 2

This photo shows how accurate the pan and tilt stop is. After moving around for a while I stop suddenly and the pan and tilt head stops central to my face. You can see in this photo of the fold out lcd monitor on the Z1 that the crosshairs aim between the eyes.

This video shows a limiting error when using the facial recognition in an uncontrolled lighting environment. The brightness of the light confuses the software and is possibly added to by the light having sharp corners. Further tests will be conducted in a controlled environment to simulate a studio.

Haar recognition error

This is a video of the modified control box. There has also been some fuzzy logic coding implemented at this stage to give a pseudo random number. This gives the head a handheld look when viewing the camera output to make it more realistic and more human like.

The data line is shared between the two digipots. This means the same data is being sent to both digital pots. The pots are switching in and out of this data at precise times via bringing the CS pin LOW and HIGH. This means the x coordinates are being handled by the x pot and the y coordinates are being handled by the y pot.

Here is the pan Motion working (sorry for dodgy camera) I will be connecting a Broadcast camera to the head in later tests

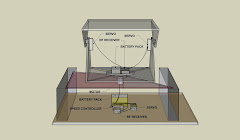

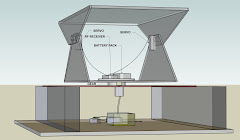

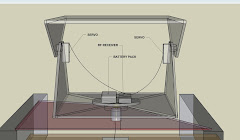

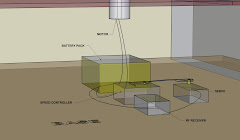

Here is the apparatus used

Test at 24v

Test at 5v

.jpg)

.jpg)